Technical and safety analysis of nuclear power technology - Paks 2 EN

Technical and safety analysis of nuclear power technology

During nuclear power plant construction projects, it is important for the investor to keep in mind a system of requirements that focuses on safety, which will take into account the legal requirements and standards for the application of nuclear energy, as well as the specificities of the host country. In Hungary, Act CXVI of 1996 on Atomic Energy, the so-called „Atomic Act”, provides for clear conditions for the use of nuclear energy. One of the principles is that „the risk of using nuclear energy is not greater than the socially accepted risk of other activities”. The Atomic Act requires the establishment of a national regulation that complies with international standards, which will ensure compliance with the safety requirements for nuclear power plants. In accordance with the provisions of the Atomic Act, Government Regulation issue nr. 118/2011. was issued, as well as its annex the Nuclear Safety Regulations (NSR), which covers the „nuclear installations, their systems and system elements, which are already in operation in the territory of Hungary, and the activities related to the nuclear facility and those carrying out this activity”, and is designed to ensure the safe use of nuclear energy.

In the case of the establishment of a nuclear power plant, in addition to domestic legislation, the recommendations of international organizations and the experience and knowledge gained worldwide in the operation of nuclear power plants need to be considered. Nowadays, taking into account the experiences of the Japan Fukushima Dai-ichi nuclear power plant accident is also a fundamental requirement.

If we establish the technical and nuclear safety requirements, in this light we can evaluate the technologies offered by each potential supplier and compare their characteristics.

Let me present that due to the properties of the reactor technologies available on the market and the European and domestic requirements, the nuclear power plant technology offered by the Rosatom Group is the most suitable for Paks II. project implementation, moreover this is the only one that can meet the domestic technical and nuclear safety requirements.

Type and generation of nuclear power plant

The majority of currently operating nuclear power plant units are light water cooled, light water moderated, most popular among them PWR (Pressurized Water Reactor) reactor types. Second most common type is BWR (Boiling Water Reactor) nuclear power plant, however, its acceptance was significantly reduced as a result of the Fukushima nuclear accident.

Briefly about PWR and BWR technologies

The water used as coolant in the reactor's active zone in BWR reactors (during normal operation) boils, then the vapor thus produced drives the steam turbine. The mechanical energy produced by the turbine is transformed by the generator into electric energy. The tired steam leaving the turbine is condensed and then returned to the reactor. BWR power plants therefore do not require a steam generator, a two-circuit cooling system is used.

In the PWR reactors, contrary to the above, high pressure water cools the heating elements in the active zone of the reactor, the steam driving the turbine is generated in a special heat exchanger, in the steam generator. By using the steam generator, zone cooling radioactive medium does not come into contact with the turbine. PWR power plants therefore use a three-circuit cooling system.

In the case of reactors currently under construction, the dominance of PWRs has continued to grow, already exceeding 80%, while the BWRs fell below 10%. Similarly small is the share of other reactor types (e.g. heavy water units) among the units currently built, and these power plant types also require additional technologies during their operation (e.g. heavy water operation), for which there is no experience or infrastructure in Hungary. A much smaller amount of resulting spent fuel is a big plus for the PWR technology compared to the heavy water reactor technology.

Taking into account the technological features and market trends, as well as the fact that significant expertise has been accumulated in the construction, operation and maintenance of pressurized water reactors in the currently operating units of Paks Nuclear Power Plant, limiting the PWRs of the concerned reactor types is absolutely grounded and necessary for our country.

Out of the currently available pressurized water reactors on the market there are only a few types which belong to the most up-to-date 3. or 3+ generation reactors. Since only the 3. and the 3+ generation reactors are able to meet the current strict domestic nuclear safety requirements, only these could be discussed in the case of the new Paks units, preferring the 3+ generation, which has even more advanced security solutions.

About the generations of nuclear power plants in a nutshell

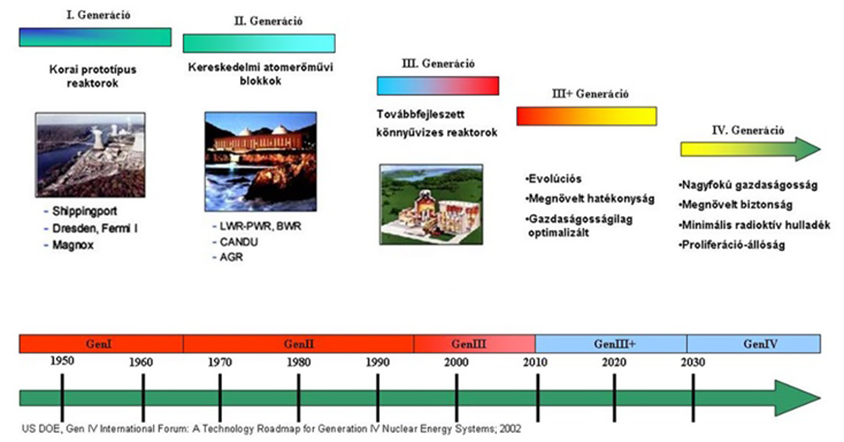

Utilizing nuclear energy is a relatively young type of power generation. The first, mostly prototype reactors were built in the second half of the 50s and in the 60s, they are called the 1. generation nuclear power plants, they do not operate anymore.

Based on the experiences gathered in the operation of the 1. generation power plants, the 2. generation models were developed, which were mainly built in the 70s, 80s and smaller parts of the 90s. The majority of currently operating nuclear power plants are 2. generation nuclear power plants, including the Paks units.

Utilizing the operational and safety experience of the 2. generation nuclear power plants, the 3. generation reactor types were created in the 90s using analytical and design methods developed over time. The main directions of development were to increase security, improve economic competitiveness, nuclear safeguards and sustainability requirements.

Further optimalization of 3. generation reactor resulted in the birth of 3+ generation in the 2000s – these non-sharply distinct types on a technological basis can be considered much more advanced from a safety point of view. In the case of most of the 3+ generation reactors, the handling of events beyond the design and the use of passive safety systems are already essential. When designing these types, much more attention has been paid to developing resistance to external sources of danger, for example, some units can withstand even the impact of a large passenger plane.

Generations of nuclear power plants

The currently available 3. or 3+ generation pressurized water reactors, at least in construction phase are as follows: AP1000 (Westinghouse), APR-1400 (KEPCO), EPR (Areva), VVER-1200 (Rosatom). The construction of Atmea-1 (MHI-Areva) hasn’t been started yet, it is expected to be built on site Sinop in Turkey in the future. However, the readiness level and references of this type are significantly behind the other listed types, so this is not the subject of further testing.

Unit size, fitting into electrical network

The current energy strategy (National Energy Strategy 2030) aims to maintain a 40% share of domestic electricity generation in the long run. Following the expected decomission of the currently operating Paks units between 2032-2037 – taking into account the projected increase in domestic electricity consumption – requires a long-term operation of at least 2000 MW nuclear power plant capacity.

The gross capacity available on the market for pressurized water units corresponding to nuclear safety requirements varies between 1100 and 1700 MW. Taking into account the facilities of domestic electricity system (security of supply, operational safety, system control, reserves), and the costs of fitting each type into the system, the extreme big size (the EPR unit’s 1600-1700 MW net capacity) is not suitable for the domestic electricity system.

Nuclear safety features, compliance

The starting point of the Hungarian nuclear safety regulation is the Convention on Nuclear Safety (CNS) accepted under the aegis of the International Atomic Energy Agency, ratified by Hungary, as well as the basic document of the European Union's common nuclear safety, Nuclear Safety Directive (EURATOM 2014/87 directive). The requirements of these basic documents appear in the national Atomic Act and in the NSR.

General safety requirements

Domestic regulation, in accordance with the above-mentioned international regulations, is not exclusive, it does not give exclusivity to a particular type of nuclear power plant, but sets out the minimum requirements that a newly constructed nuclear power plant must fulfill. These minimum requirements have been considerably tightened in recent times – partly due to the Fukushima nuclear power plant accident and partly to the handling of security issues already encountered. Among the restrictions, it is worth highlighting the requirements set by the NSR for new nuclear power plant units. In the case of new units the zone melting frequency criteria is tightened, (10-5/year compared with the previous 10-4/year) and in case of these new reactors, the licensee must demonstrate that significant or early radioactive releases can be practically excluded during accidents („practically eliminated”). (NSR limits the cumulative frequency of large or early emission events in 10-6/year.)

Aggravations will also be needed in the future, as the continuous development of nuclear safety is one of the industry's main expectations. The new findings and the operational experience that have emerged in the development of science are backed up in the planning process by requiring a continuous review of the level of safety of nuclear power plants and, if necessary, further enhancement of it. Taking into account the above, it is advisable to choose solutions that have sufficient reserves. Based on the above, one of the most important aspects of selecting a suitable type of reactor for Hungary is compliance with strict safety requirements, with the precaution that, if possible, safety parameters that exceed the current requirements should be maintained.

The most important and complex criteria is nuclear safety. Consideration of the Fukushima experience (which has already been included in the Hungarian legislation) has in any case justified the choice of a 3+ generation nuclear power plant unit type, which, in addition to utilizing the Fukushima experience, would increase the resilience to external (natural and human) danger, and also means installing systems for the management of major accidents. Hungary has a clear interest in obtaining a "Fukushima-resistant" reactor type which, in addition to handling complex malfunctions and major accidents, is sufficiently resistant to the impact of a large passenger aircraft. This latter requirement can be met only with a robust, double-walled containment (double-walled hermetic reactor with protective structure). In order to handle major accidents, reliable localization and cooling of molten fuel is required, which presupposes the existence of melting systems. A basic requirement is the application of the so-called „defense in-depth” principle and the proper separation of the different depth protection levels. In addition, the storage reservoirs of spent fuel must be dimensioned for various serious malfunctions and external risk factors. In addition to the legal regulations in force, the requirements of the Hungarian party are based on the so-called „EUR” (European Utility Requirements) criteria.

The Korean-designed APR-1400 reactor type – although it incorporates some advanced security solutions – does not meet the above-mentioned basic requirements (e.g. missing the double-walled containment, having a two-fold redundancy instead of a four-fold one in the safety electrical supply, etc.) thus it cannot be treated as a 3+ generation type, so it is not the subject of further testing.

According to the Hungarian NSR’s 3/A volume 3a.2.1.2400 point „Safety-critical systems and components have to be designed with proven design solutions that have been tested under similar conditions. Otherwise, technologies and products that have been tested and verified have to be applied. In the case of new design solutions that are different from those in the technical practice, applicability must be verified by means of adequate research, tests and other experience gained in other applications.”

From the tested systems’ perspective, the evolutionary reactor types (EPR, VVER-1200) have a clear advantage over innovative types (radically new technical solutions) (e.g. AP1000), since the former’s systems for handling planned malfunctions have already been tested and used in nuclear power plants already in operation. Regarding the VVER-1200 such references – in the case of the double-walled containment or the melt trap – are the already built and operating Chinese Tianwan nuclear power plant’s AES-91 units and the first operating unit of the Russian Novovoronezh-II NPP. Other such units are also being built or put into operation in several countries.

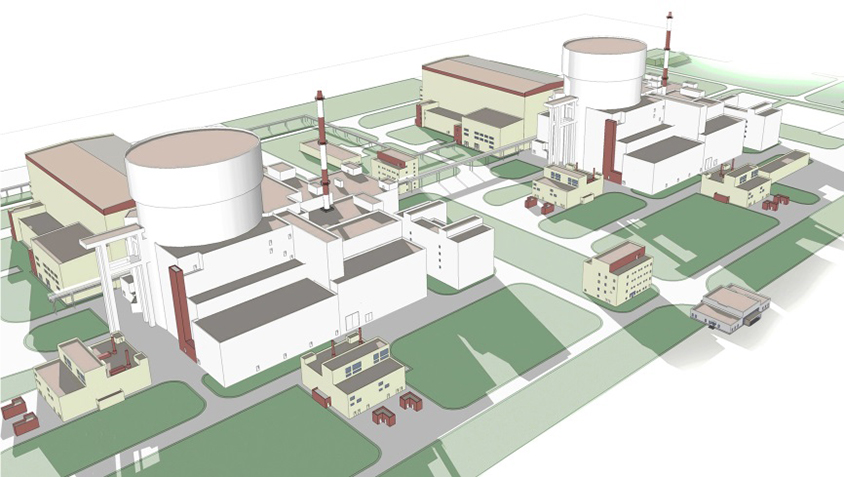

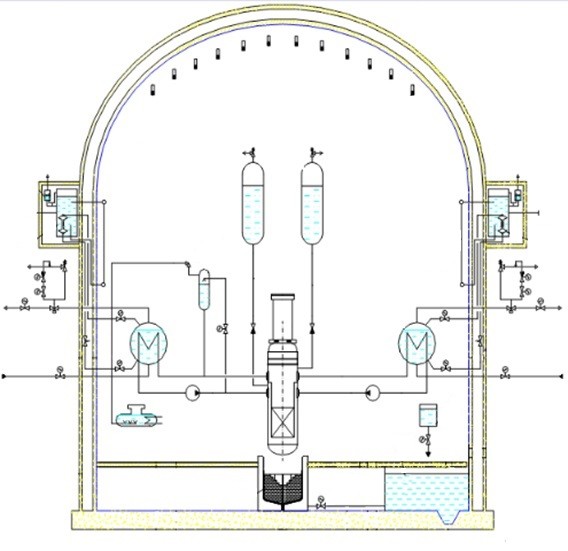

Graphic design of Units 5&6 of Paks II. NPP

Double-walled hermetic protective building

Among the security systems, it is imperative to emphasize the requirement of a double-walled containment, which is also included among the specific requirements of the Hungarian party. Generally speaking, in a double-walled containment, the inner containment wall plays a crucial role in the localization of radioactive materials within the facility, while the outer wall provides protection against external sources of danger (e.g. impact of a plane, meteorological effects, etc). In the case of full duplex containments – i.e. when the outer wall encircles the entire inner containment and seals it hermetically – the enclosed space between the two walls, annulus means a further level of protection, since in this case the air of the annulus can be kept depressed, the medium therein can be vented and filtered, so the leakage of the inner wall can also prevent the release of radioactive substances into the environment. This – the exhaustion of the closed space between the two containment walls and the existence of a ventilation and filtration system for this purpose – is required by the NSR.

The significance of a robust containment and the coolability of the containment are also an important lesson of the Fukushima accident, as the system designed to reduce pressure in the containment, the so-called filtered drainage was virtually useless in Japanese units hit by the tsunami.

It is clear that the double-walled containment provides more protection to the environment (and reactor) than the single-walled protective building used for older types. Like the EPR, the VVER-1200 has two full-featured, sealed enclosures, the annulus is enclosed in the entire space between the two walls, so that the inner wall is surrounded by the secondary (outer) containment. Cooling of the containment with cooling systems with sufficient redundancy is ensured in every operating condition.

The AP1000, on the other hand, has a partial double containment, the inner whole containment is hermetically sealed, with an approx. 5 cm thick steel wall, while the outer reinforced concrete wall (protective building) is not hermetically sealed, openings are provided to ensure the airflow required for passive cooling of the inner containment. In this case, only the lower part of the annulus is closed and the suction is ensured from here. The EUR requirement system recommends the more significant connections of the annulus areas to ensure extraction.

The EPR’s and VVER-1200’s containment system consists of two full cylindrical walls and dome closures that each contain approx. 1 m thick reinforced concrete structures (inner wall is pre-stressed reinforced concrete). The entire secondary containment can obviously provide a significantly better protection against external influences (e.g. fire, explosion, chemicals, flying objects), and also allows for the atmosphere of the complete annulus (the ring space between the containment walls) to be checked and cleaned in case the primary containment is damaged. Due to the enclosure of the outer containment wall and the thick reinforced concrete wall of the inner containment, the complete double-walled containment is better protected against an impact of an airplane, considering the mechanical effects of the aircraft and the protection against fire following the impact.

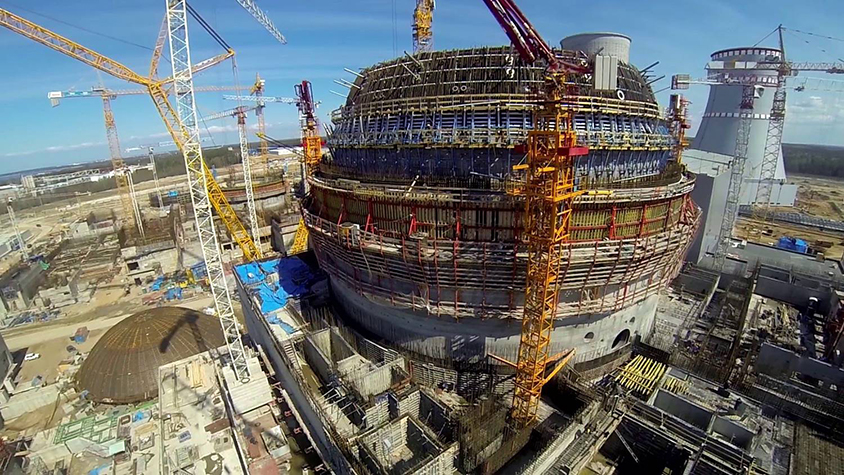

Leningrad-II using VVER-1200 technology. Containment of the nuclear power plant under construction (Source: rosatom.hu)

In the case of AP1000, the partial double containment raises safety concerns, as in this case the outer protective building is not leakproof and the upper part of the annulus is in direct contact with the environment, so the suction can not be avoided and any possible radioactive material can not be filtered out. As a result, the AP1000's external protective building has no pressure-holding or localization function. In the case of complex malfunctions and major accidents (OSD – operational state of the design base extension), the AP1000 can be depressurized by heat transfer through the inner containment wall, to which natural air flow through the openings of the outer protective building and passive injection from the water tanks at the top of the protective building are also required. This solution is less robust than the full double-walled containment from a security point-of-view, with a weaker localization feature, some external effects can also significantly affect the type. For example, there is a question of whether the internal containment is adequately protected or the availability of passive containment cooling due to an impact of an airplane or external fire. In the case of damage to water tanks or damage to the natural air flow path, the AP1000 can only reduce the containment pressure by means of filtered container leakage but this is to be avoided in OSD operating conditions based on the requirements set by the Paks-2 project.

Placement of spent fuel storage pools

An important issue – also based on the experience of the Fukushima accident – is to protect the spent fuel against external influences and to ensure the heat loss of spent fuel in case of complex malfunctions. The requirements set out in the Paks-2 project, based on the above mentioned experiences (and safety), provide for the same level of protection against all external dangers, regardless of whether the fuel is contained in the reactor or in the pool. The spent fuel storage pool has significantly better protection against external risk factors when placed inside the containment (and of course, a better level of environmental protection when the containment is double walled). This solution is applied to the VVER-1200, while the EPR and AP1000 types have a storage pool for spent fuel that is located outside the containment. This also gives VVER a greater security. (For the EPR, the fuel management building's external protection is the same as that of the containment, but for AP1000 this level of protection is questionable, for example, in the case of shielding against an impact of a plane.)

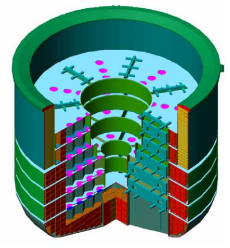

Handling zone melt during major accidents

Another important issue is the handling of major accidents involving zone meltdowns at different reactor types. According to the requirement set out in the Paks-2 project, conservative principles should be applied to the design of physical damages in the localization of radioactive materials in order to avoid the so-called „cliff edge effects” so that these barriers should be designed with significant safety margins (This recommendation is also provided by the International Atomic Energy Agency's safety instructions [No. SSG-2]).

An enhanced safety level for zone-melting major accidents in the VVER-1200 and EPR is the zone melt trap. This safety system is also capable of absorbing and cooling the molten fuel in the case of a major accident involving nuclear fuel melting in the ex-vessel phase (after projected damage to the wall of the reactor vessel). This EPR and VVER-1200 reactor zone melt trap system has a significantly higher reliability than the AP1000 type’s so-called IVR strategy’s (in-vessel retention – retention of zone melt inside the reactor vessel by external cooling of the reactor vessel’s wall) reliability, in the latter case, if there is a possible damage to the reactor vessel, there is usually no additional installed system for fuel melt handling. According to the calculations of the US Nuclear Safety Authority, the damage to the reactor vessel wall in the case of external cooling of the vessel may also be relatively probable for larger reactors, such as AP1000, which questions the existence of required reserves for the AP1000 reactor.

Based on the above – and other aspects not detailed here – it is clear that only the VVER-1200 technology complies with the strict nuclear safety and technical requirements set by the Paks-2 project company which takes into account Fukushima experience.

Other (Operational and Licensing Experiences)

When assessing the types, it is also important to note that the current Paks units are also of Russian (Soviet) design, and as a result, over the past three decades in our country over 120 reactor years of operational, maintenance, licensing and educational experience accumulated regarding the Russian pressurized water reactors, and close cooperation with Russian designers, contractors, researchers and companies operating similar power plants were established. (It is to be noted that the present Paks units are still members of the 2. generation, designed in the seventies, so the design of the VVER-1200 units varies considerably from one point to another, for example structural materials, fittings and systems – but it is very similar to the VVER-440.) This experience in the implementation of the project, then during its operation in the field of operation, maintenance and, where appropriate, the handling of malfunctions, has very serious advantages, which must also be taken into account in the assessment.

The turbine hall of the Paks Nuclear Power Plant (Source: atomeromu.hu)

Regarding the requirements set for the new units, it is stated that the requirement for Fukushima experience and the requirement of „Fukushima-resistance” has been given a special emphasis. The supplier must provide proof of compliance with this requirement. The above-mentioned systems and other security solutions guarantee VVER-1200’s resilience to initial events and other external influences similar to those of Fukushima.

Prof. Dr. Attila Aszódi